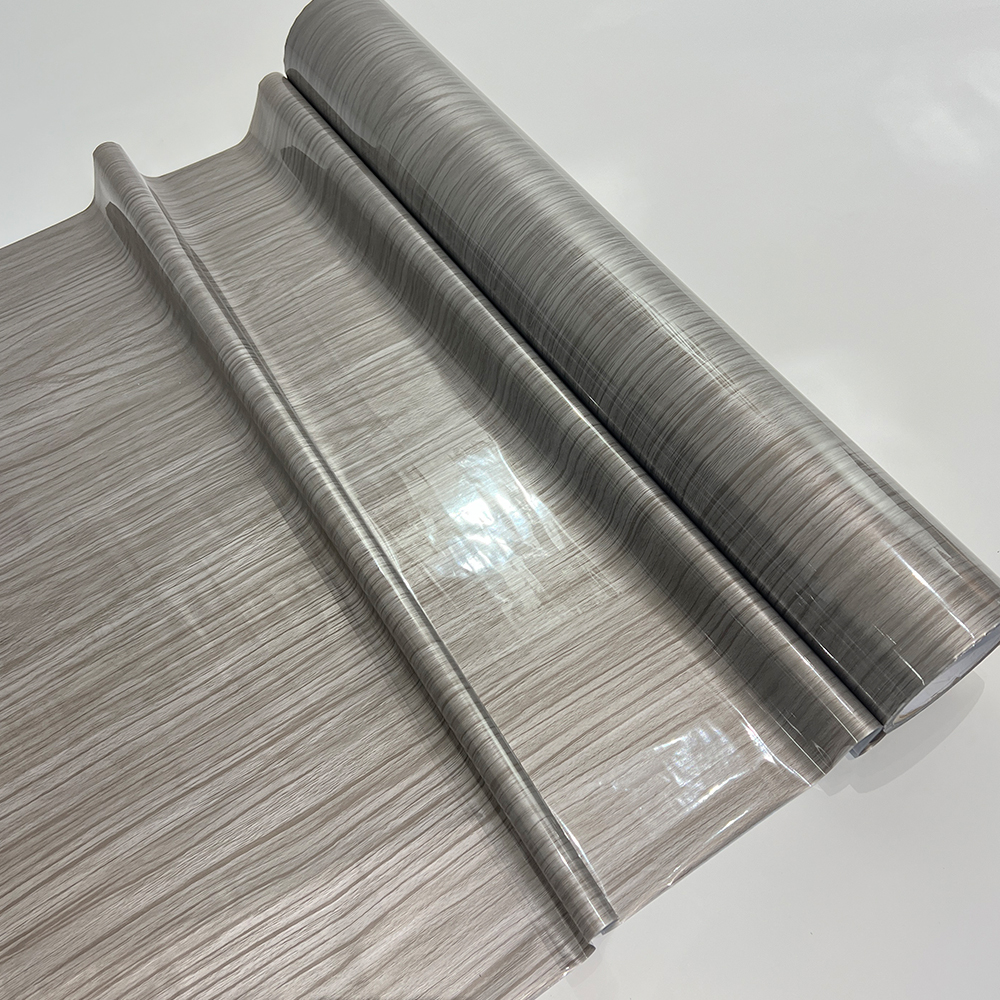

1. Using advanced heat transfer technology, the heat transfer film can be transferred to the edge strip to show a bright color and clear pattern decorative effect. At the same time, its color durability is strong, even if it is used and cleaned for a long time, it can maintain the original color and clarity.

2, ABS edge sealing thermal transfer film has good wear resistance and scratch resistance, after the transfer will form a decorative layer on the surface of the edge sealing strip, can effectively resist scratching in daily life, to maintain the integrity and beauty of the surface of the edge sealing strip.

3, ABS sealing strip heat transfer film can be firmly attached to the surface of ABS sealing strip, even in long-term use, can maintain the integrity and stability of the pattern, so that it is not easy to fall off or fade.

4, thermal transfer process and daily use, will not produce toxic gases or waste water and other toxic substances harmful to the human body and the environment, in line with the requirements of modern home environmental protection.

5, the corresponding thermal transfer process is relatively simple, the whole process is simple, high efficiency, greatly improve the production efficiency and reduce the production cost.

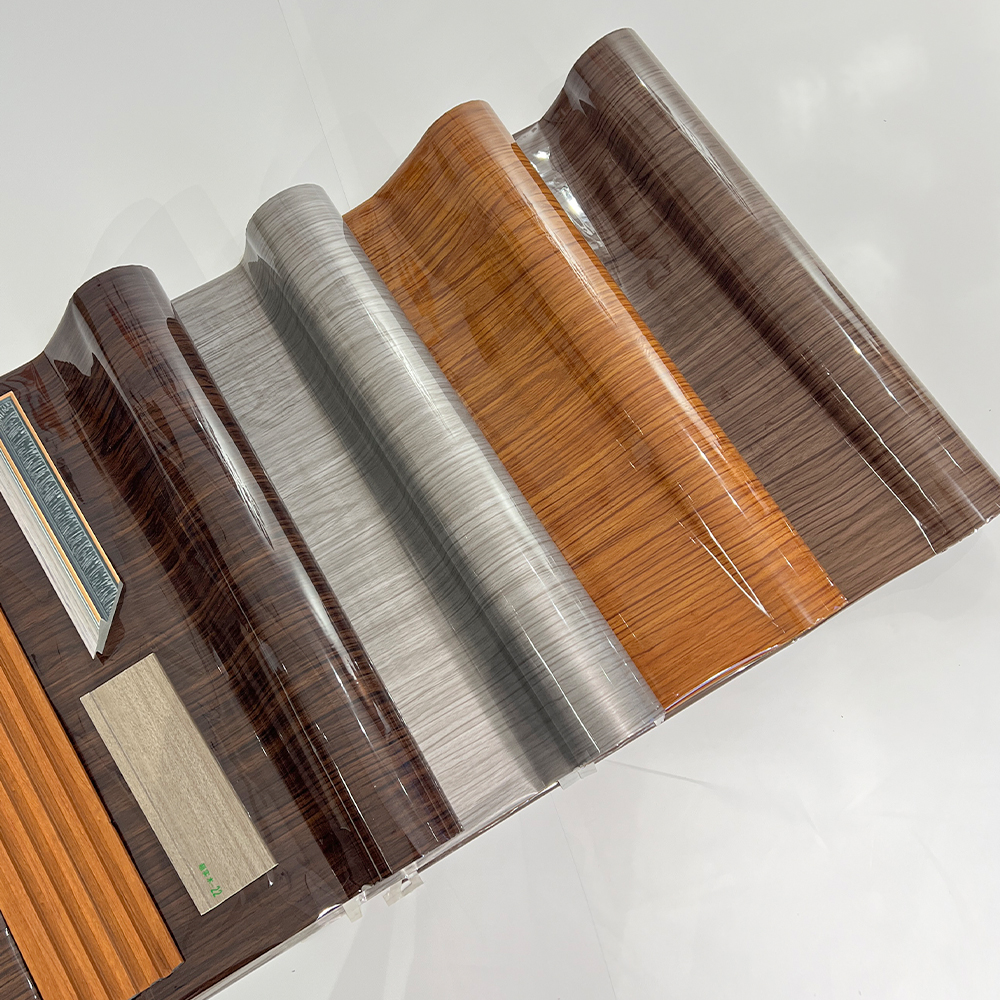

Scope of application: All kinds of PVC, WPC stone plastic decorative lines and decorative panels, ABS edge banding, PVC door panels, calcium silicate and other products. Wood plastic (WPC) door, wood plastic (WPC) door line, wood plastic (WPC) door panel, wood plastic (WPC) furniture panel, wood plastic (WPC) floor, wood plastic (WPC) decorative board, PVC skirting line and various PVC products, ABS decorative panel and other products, stone plastic line, stone plastic decorative board. PVC floor surface texture transfer, PVC foam lines and plates, acrylic edge strips, PVC edge strips and similar products.

中文简体

中文简体

English

English

русский

русский

Español

Español

عربى

عربى

Türk

Türk